Technology Transfer Track Posters

Freemelt AB

Efficient 3D printing of tungsten

Electron beam powder bed fusion (E-PBF) opens new possibilities to efficiently produce complex parts in tungsten with superior chemical purity and density.

The electron beam can be moved up to 4 km/s. This opens for spot melting where the beam creates melt pools that solidify individually. This is beneficial for tungsten because it can evenly distribute heat, reduce residual stress and additionally be used to tailor material properties.

The melting is done with a diode electron gun which has an excellent beam quality through its full power range up to 6kW. This translates to high productivity.

E-PBF is run at vacuum levels as low as 10-5 mbar. This not only prevents oxygen pickup, but it also purifies the tungsten from oxygen as the material is fused.

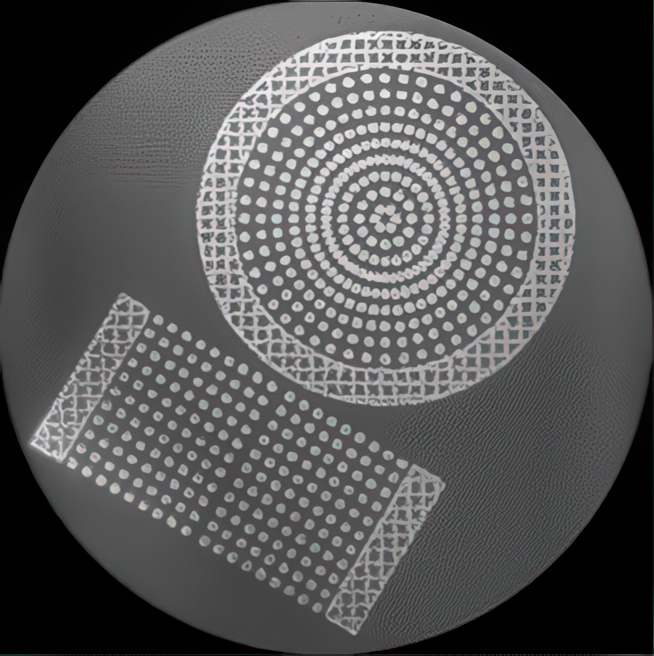

Freemelt uses a robust backscatter electron detector for in situ monitoring, according to the same principle as an SEM. This is particularly useful for tungsten which is notoriously difficult to examine with non-destructive testing methods.