Technology Transfer Track Posters

F4E/ Axist

Automatic Metrology Device

Axist presents the Housing Inspection Tool (HIT), a state-of-the-art automatic metrology device designed to measure threaded hole characteristics with exceptional accuracy in under 5 minutes. Utilizing advanced technology, including spot laser sensors and linear encoders, HIT provides detailed geometric data and detects potential defects. This portable, CE-marked device is adaptable to various shapes and geometries, making it a versatile tool for quality control across numerous industries. HIT’s integration with Industry 4.0 allows real-time comparison with CAD models, enhancing operational efficiency and precision. Ready for immediate deployment, HIT is available for direct use and technical adaptation for new applications.

F4E/ Viromi

Fusion Technology Transfer Award

The Fusion Technology Transfer Award aims to highlight and reward projects that integrate fusion solutions in non-fusion applications. Open to European entities, the award offers a 10.000 € prize for an outstanding fusion technology transfer project. Applications are evaluated based on socio-economic impact and efforts to commercialize fusion technologies in non-fusion markets.

F4E/Natec Ingenieros

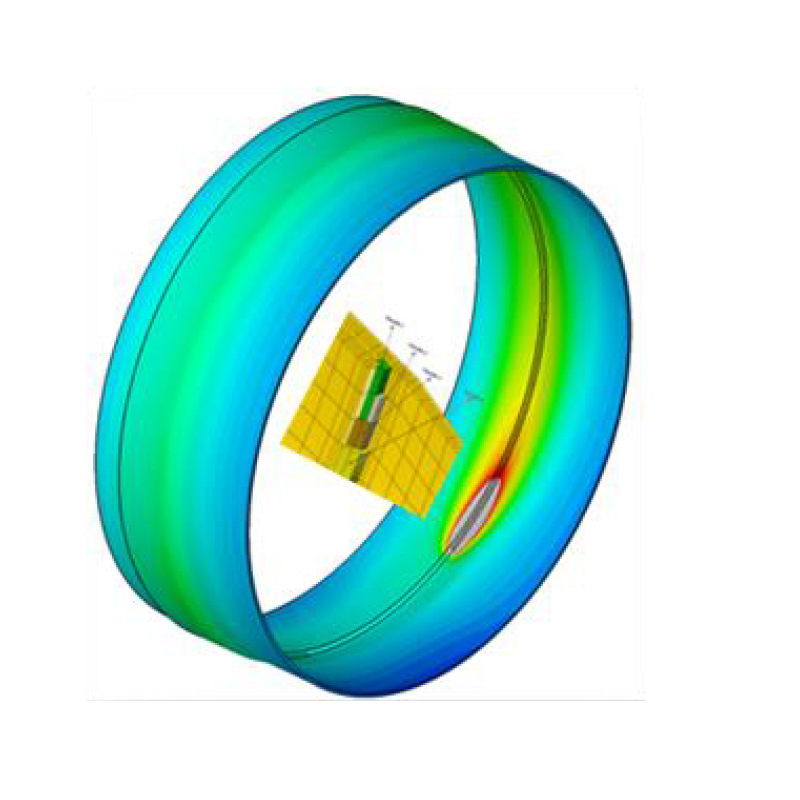

Weld Deformation Prediction

Natec presents the Welding Distortion Analysis (WDA) tool, a cutting-edge simulation and analysis technology designed to predict the effects of welding on massive and complex assemblies. This step-by-step thermo-mechanical simulation tool optimizes manufacturing processes and jig structures, ensuring the highest quality and dimensional accuracy of final equipment. WDA is ideal for industries requiring precise control over welding-induced distortions, such as building and public works, space, nuclear facilities, and electronic cases. The technology is available for engineering support services and expert advice, offering extensive applications in fusion reactors, oil and gas facilities, and architecturally complex infrastructures.

F4E/Diamond Materials

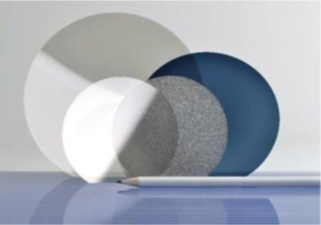

Innovative diamond materials

Diamond Materials is at the forefront of innovation, producing diamond discs that exceed the properties of natural diamond. Utilizing a chemical vapor deposition (CVD) process, pure diamond discs that can transmit beams of extreme power are produced. Not only do these plates match natural diamond in terms of low absorption, extreme hardness, and high thermal conductivity but also offers broad band optical transparency and chemical inertness. The diamond plates, available up to 150mm in diameter and 2000µm in thickness, are ideal for applications including windows for high-power radiation (microwave, X-ray, laser), X-ray anodes, UHV windows for beamlines, fluorescence screens for synchrotrons, beam splitters for FTIR spectrometers in outer space, for example. The company is willing to explore and develop novel applications for these advanced diamond discs.

F4E/VAC-TRON

Glass to Metal Seals Technology

VAC-TRON has developed an innovative Glass-to-Metal Seals technology, offering hermetic interconnections essential for passing electrical signals between hostile atmospheres. Developed for the ITER project’s In-Vessel electrical feedthroughs, this technology excels in high resistance to temperature and pressure. It features a glass barrier that enhances safety and reduces weight, making it ideal for applications in aerospace, Big Science facilities, oil and gas, and hydrogen. The versatile design supports multiple signal types, ensuring cost-effectiveness and high performance. Complying with standards like MIL-STD-883 and ITER quality requirements, this technology is set to meet stringent industry demands.

F4E/Bimo Tech

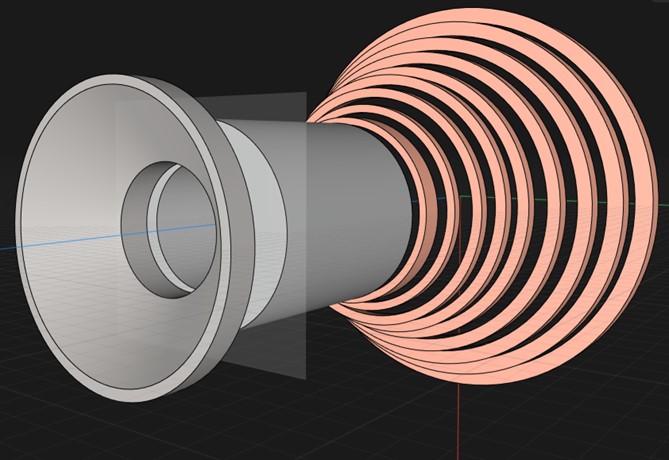

VECTOR - Nuclear Fusion Engine for Rocket Propulsion

The VECTOR Engine is a revolutionary fusion propulsion system for space exploration, utilizing advanced technologies like MIC, ICF, and HETs to achieve efficient and high-thrust propulsion. It leverages pB11 fusion for minimal radioactive waste, making it ideal for long-duration deep space missions. This system offers significant potential for both energy generation and propulsion in space, providing a versatile solution for future aerospace needs.

F4E

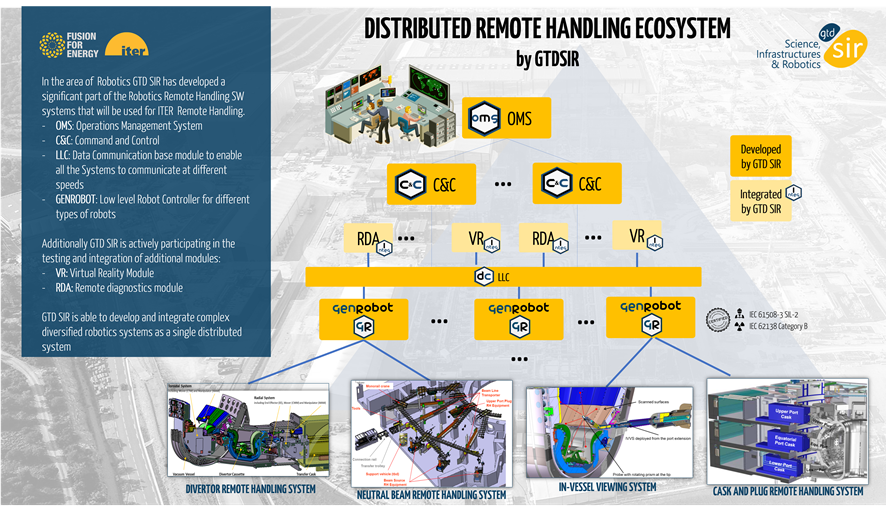

GENROBOT

GENROBOT is a high-quality industrial software which is being integrated in robots for safe and precise control of operations. The GENROBOT software can now be used with any kind of robotics equipment for critical operations such as handling systems.

GENROBOT is a generic low level control software, capable of controlling multiple manipulators in parallel. This software is fully configurable, customizable, compliant with SIL-2 and Category B standards.

This software allows to install a sense of harmony in the operating system by rigorously controlling and coordinating multiple equipment. Engineers can easily adapt and configure it to operate many robotic systems resulting to important time and cost savings. You only need to code and test 20% of the functionality. GENROBOT will speed up the time-to-market. It can be trusted with any personal or infrastructure safety-critical tasks.

The software is now ready to enter the robotics market and be used in various fields such as remote handling (nuclear decommissioning, tele-surgery), logistics or the production of equipment (robotic arms, telehandlers, material handling equipment).

F4E/ University of Basel

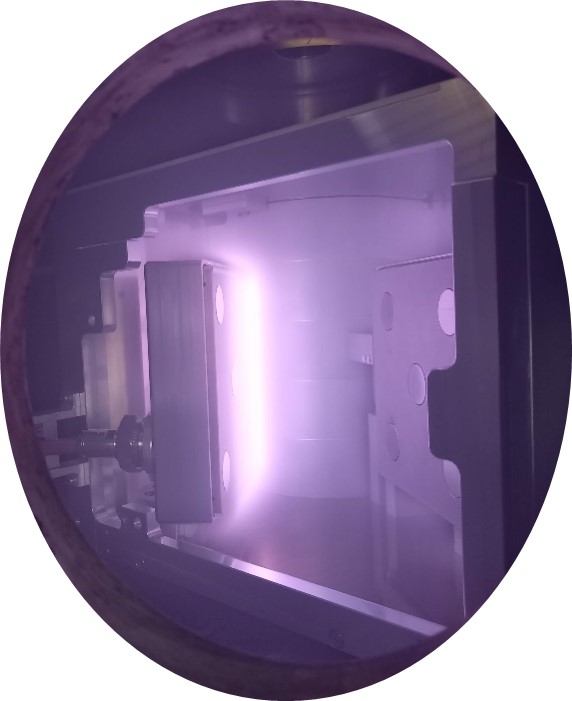

Radio Frequency Plasma Discharge Optics Cleaning

The University of Basel, in collaboration with F4E, presents a cutting-edge RF discharge technology for the remote cleaning of optics in harsh environments. Essential for maintaining cleanliness in optical diagnostic systems within the ITER fusion device, this technology uses a systematic methodology to determine optimal cleaning parameters and monitor cleanliness in real-time. The innovative approach extends the lifespan of optics by providing effective and homogeneous cleaning, applicable to various shapes and sizes. This technology is ideal for sectors requiring regular optics cleaning, such as space propulsion, industrial plasma processes, and biomedical fields. Collaboration opportunities are available for adapting this technology to new applications.

F4E/ UNED

GEOUNED

GEOUNED is a software tool that transforms CAD models into Monte Carlo (MC) radiation transport models, with the ability to convert back to CAD. It is an open-source tool, accessible, easy-to-install, that uses Open CASCADE as its geometry engine and FreeCAD as its Python API.

The software stands out for its features like decomposition and automatic void generation, especially beneficial for intricate 3D models in fusion neutronics like the ones found at ITER. The decomposition algorithm allows complex CAD solids to be broken down into parts that can be converted to Monte Carlo formats. On the other hand, automatic void generation is an innovative feature that avoids human errors when defining the existing space between components.

It has been developed as a Python API to allow scripting capabilities for task automation. It uses open-source codes such as Open CASCADE and FreeCAD, making it an easy-to-install and more accessible tool.

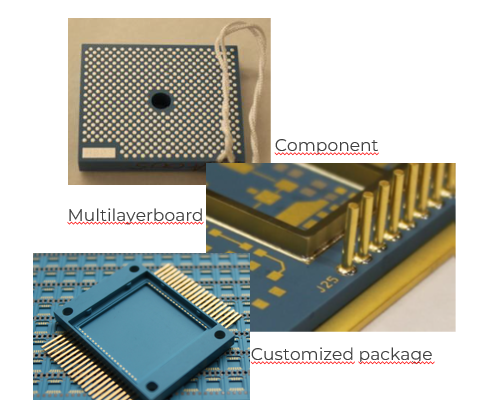

F4E/Via-Electronic

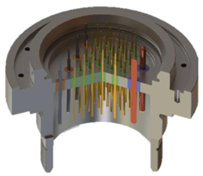

LTCC Multilayer Ceramic

LTCC Multilayer ceramic allows manufacturing of ceramic multilayer boards, packages or components. Integrated components like resistor, inductance or capacitor lead to miniaturized and robust modules applicable for harsh environments.

VIA electronic developed a manufacturing method for a coil for F4E used in the diagnostics module to measure the magnetic field. Therefore a multilayer ceramic design was done with 38 layers. Conductive tracks of the coil were printed (thickfilm technology) and connected by electrical vias. After stacking, lamination and sintering a very robust component with very accurate dimensions was the result. All parameters were inside the specified tolerances and a specific interconnection welding method for a silver wire was developed.

Generally with the LTCC technology real ceramic multilayer designs result as components, boards or packages for bare dies, MEMS Sensors, Microsystems or System in a Package SiP.

Fields of application are: harsh environment, Interposer, HDI-Designs, Image sensors, x-ray sensors, industrial, medical, aerospace, high frequency like radar or special scientific application.

Further special technology features are:

– Ceramic caps with and without metallization

– side metallization for limited assembly space

– thermal vias

F4E/Walter Tosto/Ansaldo Energia/Mangiarotti

PAUT-AI

PAUT-IA are a series of AI-based tools aimed at accelerating the analysis of PAUT outputs when evaluating welding defects. This will allow a decrease in time and cost in the evaluation process while minimizing the human error factor.

The AI models were designed to detect welding defects in the manufacturing process of the ITER Vacuum Vessel. The prediction obtained is presented in a way so that a human expert can confirm the potential weld defects identified.

The major benefit of this technology is that its successful application would reduce time and operational costs significantly, as well as improving Early Data Analysis during the manufacturing process. The implementation of the models indicated would allow for decreasing the processing and interpretation time of PAUT output from a week to just several minutes, providing prompter data that will help to take informed decisions.

The results obtained with these AI models indicate that they aim to be a breakthrough approach in use cases where a big amount of PAUT output needs to be processed, for example the manufacturing of pressure vessels. Given that the output prediction provided by these models is much shorter than that of human interpretation, the use of this tool should save at least 95% of the time taken by a human in a regular evaluation.

F4E/ EUROfusion

Portfolio of Fusion Technologies

Unleash your business potential with fusion technologies.

The European Fusion Technology Marketplace results from a partnership between Fusion for Energy (F4E) and EUROfusion, covering international research programmes and projects such as ITER, DEMO, JT-60SA, IFMIF and IFERC.

We encourage companies looking for new technologies to discover the breakthroughs in fusion and integrate them into their businesses. Our aim is to promote the technologies developed by Fusion for Energy (F4E) and the European Fusion Laboratories (EUROfusion) by making them widely available and commercially viable to industry.

Visit us https://fusion-technology-transfer.europa.eu/ and Contact us through the Contact us form of the website.